Wow, Looking back on this week it has been a blur. Nashira was lifted onto the hard stand on the 1st of March with Rod of RM Marine assigning Cameron as our shipwright to assist us with repairs.

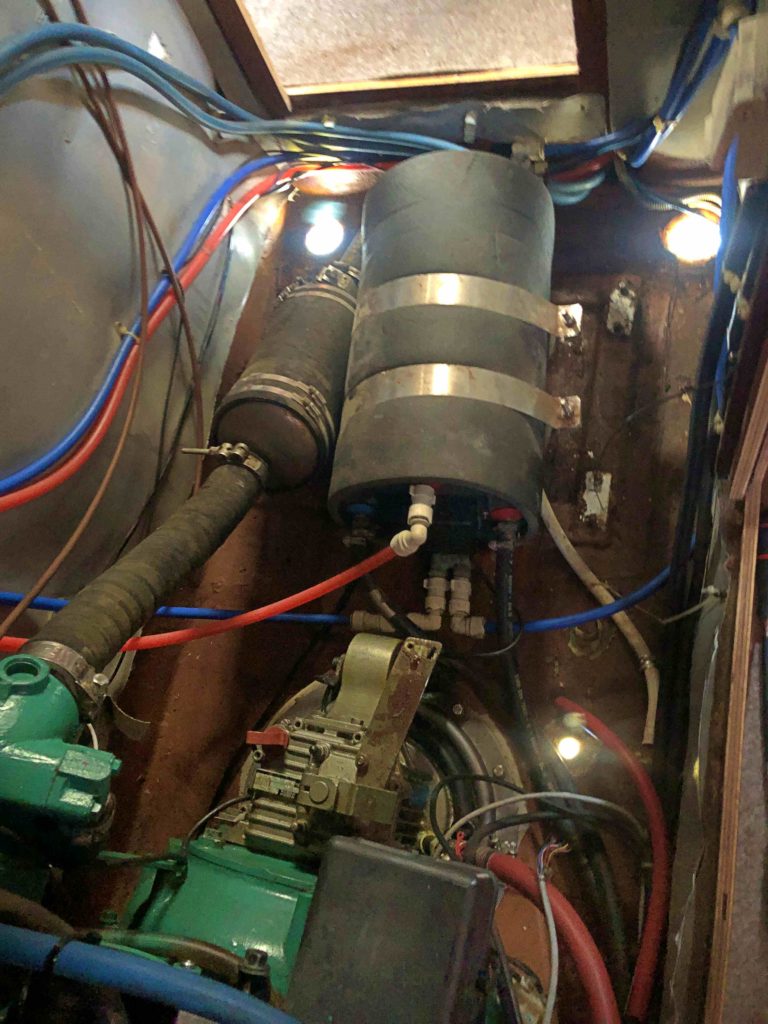

With the new and refurbished steering cables ready we have a list of things to handle before re-installation occurs. Getting the Generator exhaust pipe and muffler taken out for one and glassing over the old exhaust through hull fitting. This has given us extra space and a clean line for relaying the steering cables.

With the new and refurbished steering cables ready we have a list of things to handle before re-installation occurs. Getting the Generator exhaust pipe and muffler taken out for one and glassing over the old exhaust through hull fitting. This has given us extra space and a clean line for relaying the steering cables.

We chose to have the cockpit drains redone as there has been some electrolysis noted on the through hull fitting. [Note: In hindsight this has cost us extra time and effort but hopefully was the right call to get it replaced]

We replaced another through hull fitting (the salt water pump), replaced the breather valves for the holding tank, replaced the topping lift. Replaced the cabin water pump and had the Keel faired from the damage sustained in Triabunna when we hit a rock.

During the day Evan and I worked to make things easier and faster for the shipwright. In the evenings we would have dinner with friends or eat at the Oyster Cove Inn just behind the marina. Hobart showed off weather from 37 degrees (sweltering in the engine bay) down to a 15 degree high one day where winter jackets were brought back out to work. The weather is NEVER boring.

I learned how to use the grinder to remove paint from the old generator stand and repainted it with rust inhibitors. It looks great reinstalled in the engine bay.

On Friday the 8th of March we were put back into the water. About 2 hours later it became painfully obvious that one of the cockpit drains was leaking pretty badly. So back out of the water we went. Cam our shipwright took both fittings out and pressure tested them only to find they leaked in the threads. He then found instructions on the fitting to use Teflon tape (he had used liquid seal instead) So with renewed knowledge he refitted them with teflon tape and back into the water we went. This time leaving us is the sling in the water to see if we are still leaking.

Yep! This time the other fitting is leaking. Good grief, does not instil a hug level of confidence. So once again lifted in the sling to get us out of the water Cam went to work.

Turned out that the fitting had been overly tightened, that momma did not want to come out. When with Evans help they got the fitting out Cam re Teflon taped the threads and reinstalled. Back in the water again and so far things look okay.

We continued to check throughout the day and it seems okay. Our goal is to leave for Sydney (attempt number 2) on Monday afternoon at high tide to get through the Denison canal.

It would be ideal to do some sailing over the weekend as a shake down sail to make sure everything is operating as it should.

Wow, shows it certainly pays to double check anything through hull that has been changed before heading off, even if done by a shipwright